Tubiplast Product Certifications

This section contains certifications and technical information about our products

- Multilayer Pipes Specifications

- Multilayer pipe test report Istituto Italiano dei Plastici IIP

- Multilayer Pipes Certification, Milan Polytechnic

- Multilayer Pipes Certification, Istituto Giordano S.p.A.

- PP-R Pipes Certification

- PP-R pipe test report Istituto Italiano dei Plastici IIP

- PP-R Pipes Non-Toxicity Certification, Politecnico di Milano

- PP-R Pipes Pressure Resistance Certification, Politecnico di Milano

- PP-R Pipes Certification, ASL Salerno

- Copper Pipes for Heating Specifications

- Copper Pipes for Air Conditioning Specifications

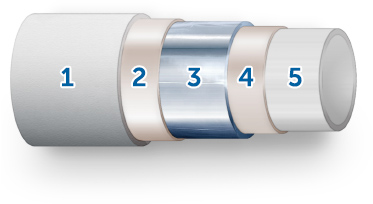

Multi-layer PEXb/AL/PEXb pipes

in coils

“Tubiplast Italy multilayer pipe” is produced and certified in compliance with the requirements of UNI EN ISO 21003.

Suitable for sanitary plumbing systems that transport hot and cold water, including under high-temperature and high-pressure, and for HVAC applications.

- Outer layer in cross-linked polyethylene (PEX)

- Adhesive layer

- Welded aluminum layer with butt-fusion technology

- Adhesive layer

- Inner layer of cross-linked polyethylene (PEX)

| Ø outer | mm | 16 | 20 | 26 | 32 |

| Ø inside | mm | 12 | 16 | 20 | 26 |

| Wall thickness | mm | 2 | 2 | 3 | 3 |

| Aluminum thickness | mm | 0,2 | 0,3 | 0,4 | 0,45 |

| Jacket thickness | mm | 6 | 6 | 9 | 9 |

| Water volume | mm | 0,113 | 0,200 | 0,314 | 0,531 |

| Coil length, unjacketed | m | 100 | 100 | 50 | 50 |

| Coil length, jacketed | m | 50 | 50 | 50 | 25 |

| Weight by meter | kg/m | 0,11 | 0,145 | 0,26 | 0,34 |

| Internal roughness | 0,007 mm | ||||

| Heat conductivity | 0,45 w/m°C | ||||

| Heat expansion coefficient | 0,026 mm/m°C | ||||

| Constant working temperature | 95 °C | ||||

| Maximum short-term temperature | 110 °C | ||||

| Maximum working pressure | 10 bar | ||||

| PEXB cross-linking | > 65% | ||||

| Oxygen diffusion | 0,00 g/l · h | ||||

| Bend radius | up to five times diameter |

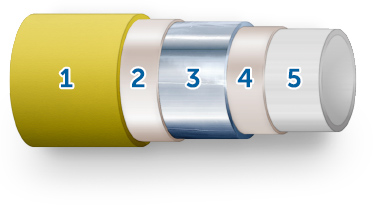

Multi-layer PEXb/AL/PEXb gas pipes

in coils

Produced and certified in compliance with the requirements of UNI/TS 11344 “Metal-Plastic Multilayer Piping Systems and Fittings for Indoor Installation for the Conveyance of Gaseous Fuels.”

- Outer layer in cross-linked polyethylene (PEX)

- Adhesive layer

- Welded aluminum layer with butt-fusion technology

- Adhesive layer

- Inside layer of cross-linked polyethylene (PEX)

| Ø outer | mm | 16 | 20 | 26 | 32 |

| Ø inside | mm | 12 | 16 | 20 | 26 |

| Wall thickness | mm | 2 | 2 | 3 | 3 |

| Aluminum thickness | mm | 0,2 | 0,3 | 0,4 | 0,45 |

| Coil length, unjacketed | m | 100 | 100 | 50 | 50 |

| Coil length jacketed | m | 50 | 50 | 50 | 25 |

| Weight by meter | kg/m | 0,11 | 0,145 | 0,26 | 0,34 |

| Internal roughness | 0,007 mm | ||||

| Conductivity | 0,45 w/m°C | ||||

| Heat expansion coefficient | 0,026 mm/m°C | ||||

| Working temperature | -20 °C / +70 °C | ||||

| Maximum working pressure | 0,5 bar | ||||

| PEXB cross-linking | > 65% | ||||

| Bend radius | up to five times diameter |

Polypropylene PP-R pipes

“Tubiplast Italy PP-R pipe” is produced and certified in compliance with the requirements of DIN 8077-8078 and UNI EN ISO 15874-2 for plastic tubing and DIN 16962 and UNI EN ISO 15874-3 for fittings and couplers.

It is suitable in sanitary plumbing systems for the transport of hot and cold potable water, including under high-temperature and high-pressure; for HVAC applications; for irrigation; and for industrial applications, including the transport of compressed air, chemicals, liquids intended for human consumption, etc.

| Ø outer | mm | 20 | 25 | 32 | 40 | 50 | 63 | 75 | 90 | 110 |

| Ø inside | mm | 13,2 | 16,6 | 21,2 | 26,6 | 33,2 | 42 | 50 | 60 | 73,4 |

| Wall thickness | mm | 3,4 | 4,2 | 5,4 | 6,7 | 8,4 | 10,5 | 12,5 | 15 | 18,3 |

| Length | m | 3 - 4 | ||||||||

| Weight by meter | kg/m | 0,176 | 0,27 | 0,444 | 0,686 | 1,037 | 1,689 | 2,409 | 3,469 | 5,04 |

| Water volume | l/m | 0,13 | 0,21 | 0,35 | 0,55 | 0,86 | 1,38 | 1,96 | 2,83 | 4,2 |

| Resistance | 20 bar / 20 °C - 10bar / 60 °C over fifty years of use |

Polypropylene PP-R pipes with glass fiber

suitable for the transport of potable water

Triple-layer piping with a middle layer composed of special fibers that reduce linear heat expansion by up to 75% compared to “normal” PP-R SDR 6 single-layer tubing.

These characteristics also reduce wall thickness, thereby increasing water transport by more than 20% compared to “normal” PP-R SDR 6 single-layer tubing.

APPLICATIONS Tubing especially suited for sanitary plumbing systems, mechanized systems, (HVAC), and the transport of compressed air or industrial liquids

TECHNICAL SPECIFICATIONS

Materials: Inner layer in PP-RCT HOR (polypropylene random copolymer, high crystallinity, high temperature, high oxidation resistance); middle layer in PP-RF (polypropylene random copolymer reinforced with glass fiber); and outer layer in PP-R (polypropylene random copolymer).

Heat conductivity at 20°C: 0.19 W/mk

Expansion coefficient: at 0.035 mm/mk

Internal roughness: 0.007 mm

Color: Green with red stripes, white tube interior

Tubing intended for the transport or liquids at a constant maximum working temperature of 70°C for 50 years at a maximum pressure of 12,5 bar.

PERFORMANCE STANDARDS

Produced in compliance with the principal international standards, including UNI EN ISO 15874, DIN 8077-8078, and ASTM. Compliant with all standards for the transport of potable water, for the transport of hot and cold liquids intended for human consumption, and for HVAC and compressed air systems.

Polypropylene PP-R pipes with glass fiber

suitable for the transport of potable water

Triple-layer piping with a middle layer composed of special fibers that reduce linear heat expansion by up to 75% compared to “normal” PP-R SDR 6 single-layer tubing.

Characteristics such as these also make it possible to reduce wall thickness which, in turn, increases water transport by more than 40% compared to “normal” PP-R SDR 6 single-layer tubing.

APPLICATIONS

Tubing especially suited for mechanized systems, including HVAC systems and the transport of compressed-air or industrial liquids.

TECHNICAL SPECIFICATIONS

Materials: Inner layer in PP-R HTS (polypropylene random copolymer Super 80 High Thermal Stabilization); middle layer in PP-RF (polypropylene random copolymer reinforced with glass fiber); and outer layer in PP-R (polypropylene random copolymer).

Heat conductivity at 20°C: 0.19 W/mk

Expansion coefficient: at 0.035 mm/mk

Internal roughness: 0.007 mm

Color: Blue with gray stripes, white tube interior

Tubing intended for transport of liquids at a maximum constant working temperature of 80°C for 25 years at a maximum pressure of 8 bar and a maximum limit temperature 95°C at 6.10 bar for 10 years.

PERFORMANCE STANDARDS

Produced in compliance with the UNI EN ISO 15874-2, 15874-5, and DIN 8077-8078 standards.